Direct-to-Film Printing Technology: Unlocking Versatility and Quality

Guide to Direct-to-Film Printing

At Oregon Screen Impressions, our commitment to innovation and quality is reflected in our diverse range of printing technologies, tailored to meet the unique needs of each client. An example of this commitment is our recent integration of the state-of-the-art Direct-to-Film (DTF) printing technology. The addition of the Pioneer 24 DTF Printer System to our lineup marks a significant leap forward, broadening our capabilities to deliver unparalleled quality, versatility, and efficiency in printing solutions.

Understanding Direct-to-Film (DFT) Printing

Direct-to-Film printing, or DTF, is a relatively new but rapidly evolving technology in the world of apparel and fabric printing. Unlike traditional methods, DTF involves digitally printing a design onto a special film, which is then transferred onto the fabric using heat and pressure. This method is known for its versatility, allowing for the use of a wide range of colors through the CMYK process and incorporating a white underbase for enhanced opacity.

Key Advantages of DTF Printing

- Versatility in Material: DTF excels in its ability to print on a variety of materials, including challenging ones like polyester, cotton, blends, and even non-textile surfaces. This versatility extends to printing on curved shapes, making DTF an excellent choice for items like hats, where traditional printing methods might falter.

- Complex Color Handling: DTF is adept at producing full color, highly detailed designs, including gradients and fine details that might be challenging for other methods. This capability allows us to offer high-quality, intricate designs that stand out.

- Superior Look and Feel: A significant advantage of DTF printing is the unique look and feel it achieves. Feedback from our clients highlights the softer feel of DTF prints compared to traditional heat transfers. This is particularly beneficial for apparel where comfort and texture are paramount.

- DTV vs Sublimation: While sublimation printing has its strengths, DTF printing offers broader versatility. Unlike sublimation, which is limited to polyester, DTF can be applied to a wider range of fabrics, offering more options for our clients’ diverse needs.

- Efficiency for Small Batches: DTF is ideal for small to medium-sized orders. It eliminates the need for multiple screens or extensive setup, making it a cost-effective solution for custom, limited-run projects.

Durability and Quality: DTF prints are notable for their durability and wash resistance, ensuring lasting vibrant designs.

When is DTF Best Used?

While DTF is a powerful tool in our arsenal, understanding when to employ this technology is crucial:

- For Intricate, Multi-Colored Designs: If a project involves detailed graphics with a variety of colors, DTF is often a great choice.

- Mixed Material Projects: For items that involve a mix of fabric types or even non-textile elements, DTF offers the flexibility needed for consistent quality.

- Short Runs and Custom Orders: Due to its efficient setup, DTF is perfect for small batches where each piece requires a high level of detail and customization.

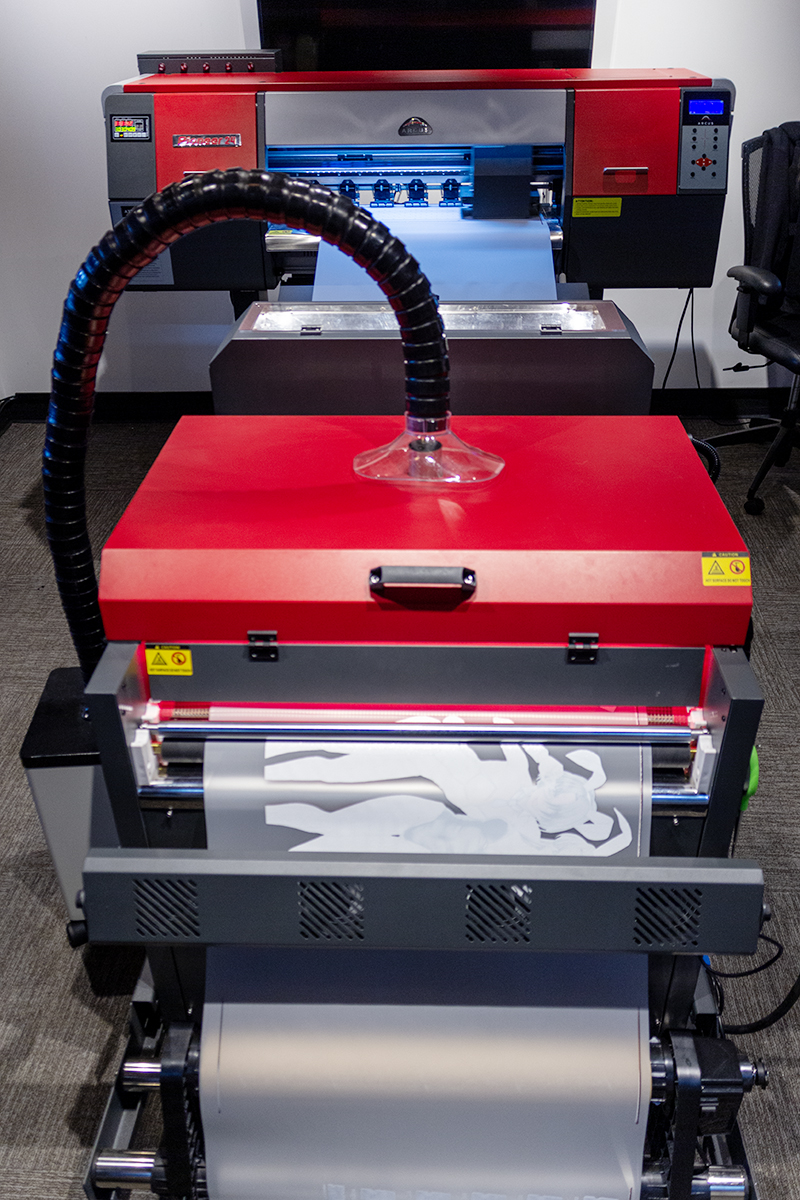

About the Pioneer 24 DTF Printer System

The Pioneer 24 is a cutting-edge DTF printer that brings unparalleled precision and efficiency to our printing capabilities. Below are its key specifications:

- Maximum Print Width: 24 inches, allowing for large-scale prints.

- Print Heads: Equipped with 2 Certified Epson I3200 Print Heads for high-quality output.

- Production Speed: Capable of printing at a rate of 110 Sq. Ft. per hour, ensuring timely completion of orders.

- White Ink System: Features a white ink recirculation system with ink tank agitation, crucial for vibrant prints on dark fabrics.

- Film Handling: An advanced film handling system ensures precise alignment of white ink over color, essential for detailed designs.

- Powder Shaker Unit: Includes a fully adjustable powder shaker unit with a powder retention system, enabling extended long production runs without compromise on quality.

Complementing Our Embellishment Capabilities

At Oregon Screen Impressions, we view DTF as one of many embellishment technologies in our toolkit. Each technique we offer, including screen printing, embroidery and sublimation, has its unique strengths. Our goal is to match each project with the most suitable embellishment technique, considering factors like the size of the order, material type, design complexity, and the desired final product look and feel.

DTF printing is a valuable addition to our range of services, enhancing our ability to provide high-quality, precision printing solutions at competitive prices. By leveraging the unique advantages of DTF, alongside our other printing technologies, we ensure that each project we undertake is delivered with the utmost care and quality that our clients have come to expect. Whether it’s a small custom order or a large-scale production, our commitment to using the right technology for the job stands at the forefront of our approach.

Need Help?

From designing to formatting, our creative department can help you end up with awesome goods you’ll love. Just let us know what you you’re looking for by starting an order, and a team member will get back to you with answers.